We are confident that in the field of CNC sheet metal processing we can offer you a comprehensive service from the idea to product development, with the help of technological capabilities in a smart factory and comprehensive technical support in product development or modification of existing ones.

Management of the production process with the help of CAD/CAM/CIM-production

Automated machine park, high-tech equipment and a wide range of tools

Laser cutting

Sheet metal punching/cutting

Bending

Grinding

Sealing

Stamping of fasteners

Edge rounding

Surface treatment

Assembly of the semi-finished or finished product according to customer's needs

- Technical support in product development and improvements: 3D simulation

- Production of technologically demanding welds, semi-finished and finished products

With you

from the idea

to the product.

- Line composition (assembly) of finished products according to customer needs

- Final assembly of metal or non-metal semi-finished products with the option of electrical equipment installation

CAD/CAM/CIM production

By choosing Elpro Križnič, you get comprehensive technical support in developing new products or modifying the existing ones. We provide strategic advice on product optimization with the implementation and possible upgrades, as well as with the costs.

Elpro’s Križnič experienced team of engineers offers you:

- Technical support in the design, construction, 3D visualization and optimization of the product

- Integrated implementation of the product (production)

- Help in optimizing production costs

Automated machine park

and tools for your needs

With a modern automated machine park, high-tech equipment and a wide range of tools, we prepare a solution for every challenge quickly and efficiently.

The machine park includes top quality machines of recognized brands.

- Automated storage system Large-storage-system

- TruBend-Cell 5000 robotic bending cell

- Trumpf TruLaser 3030 laser cutting machine

- Trumpf TruLaser 5030 laser cutting machine

- Trumpf TruBend 5230 sheet metal bending machine

- Trumpf TruBend 7050 sheet metal bending machine

- Trumpf TruBend 7036 sheet metal bending machine

- Trumpf Trupunch 5000 punching machine

- Trumpf TruMatic 7000 laser punching machine

- Machine for stamping the fasteners into sheet metal HAEGER 824 OneTouch 4e LITE

- Ernst sheet metal grinding machine

- Robotic welding machine

- Sandblasting machine

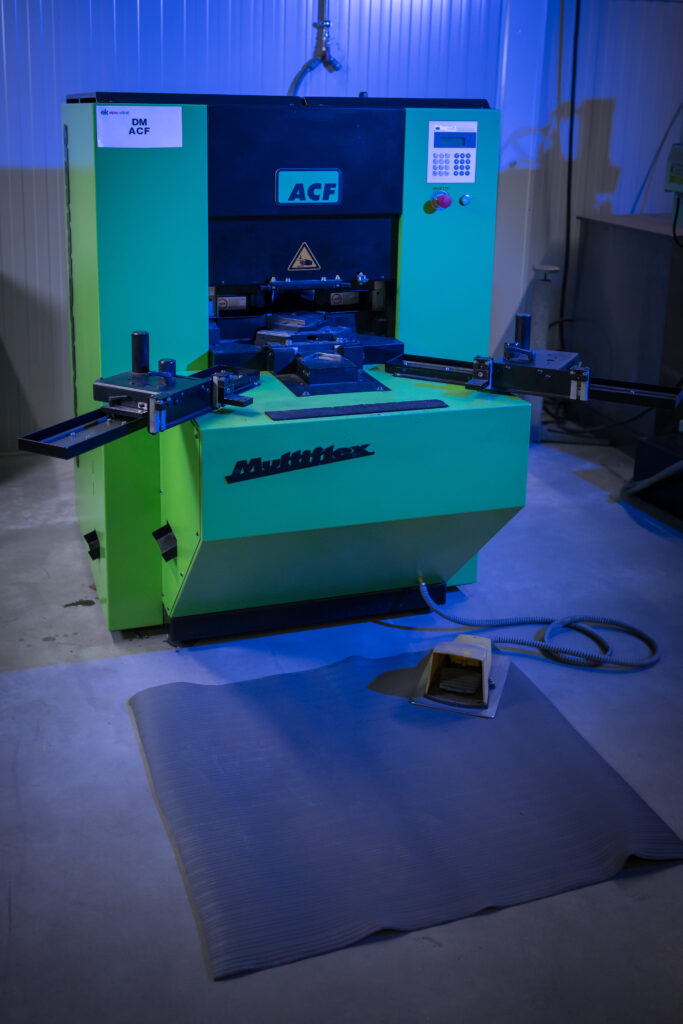

- ACF Cornerformer corner forming machine

- Sonderhoff sealing machine

Bending

Bending is a technology that claims the most knowledge and experience. In the factory we ensure the required accuracy of bending, the quality of which is regularly monitored with the help of measurement protocols.

Sheet metal bending is carried out with top quality machines:

- TruBend-Cell 5000

- TruBend 5230

- TruBend 7050

- TruBend 7036

We also offer bending without footprint, fabrication of complex parts and a wide range of bending tools.

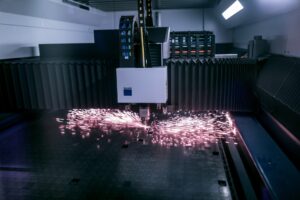

Laser cutting

With highly qualified and experienced staff and powerful Trumpf TruLaser 3030 and Trumpf TruLaser 5030 machines, we perform accurate, high-quality and cost-effective sheet metal laser cutting. The advantage of laser cutting is speed, flexible processing and numerous design possibilities.

Factory’s equipment enables the production of medium and large series with constant monitoring and performance of quality measurements.

| Materials | Thicknesses |

|---|---|

| Structural steel | up to 25 mm |

| Stainless sheet metal | up to 20 mm |

| Aluminum | up to 20 mm |

| Brass | up to 10 mm |

| Copper | up to 10 mm |

| Design dimensions | |

|---|---|

| Dimension of the machining table | 1500 × 3000 mm |

| Power | 6 kW in 8 kW |

| Accuracy of repetitions | +/–0,03 mm |

| Positioning accuracy | +/–0,01 mm |

Punching

With an experienced team and modern TruMatic 7000 and TruPunch 3000 machines, we provide affordable and technologically perfect sheet metal punching. In the factory, we process various types of materials (structural steel, aluminum, copper, brass, etc.) without thermal influence and manufacture complex products (threads, bends, draws).

In addition to sheet metal processing, we also offer sheet metal modifications, thread cutting and sheet metal bending with the help of top technology.

| Materials | Thicknesses |

|---|---|

| Structural steel | up to 8 mm |

| Stainless sheet metal | up to 6 mm |

| Aluminum | up to 4 mm |

| Design dimensions with TruMatic 7000 | |

|---|---|

| Combined machine | punch (max. 21 punching tools) + laser (2.7 kW) |

| Dimension of the machining table | 3000 × 1500 mm |

| Possibility of low sheet metal transformation (special tools) | to max. 3.0 mm thick |

Welding

Certified welders use modern welding machines to perform two types of sheet metal welding using the TIG and MIG/MAG processes:

- Manual welding (still indispensable in the metal industry),

- Robotic welding (welding with a robot is fast, precise, repeatable, flexible, productive and safe)

oduktivno in varno).

Welding services also include screw welding and spot welding.

Grinding

With the sheet metal surface grinding, we carry out accurate flash removal, edge rounding, sanding and brushing of sheet metal.

Grinding procedures are carried out on a working surface with the thickness of up to 30 mm, made of the following materials:

- stainless sheet metal,

- aluminum,

- brass.

| Tehnical informations | |

|---|---|

| Allowed thickness | 1–30 mm |

| Min size of the piece | 300 × 250 mm |

| Max size of the piece | 1500 mm |

Sealing

We meet all requirements for the appropriate degree of sealing (IP ratings). As the last stage, the sealing process (making a seal) is integrated into the technological process. We use state-of-the-art CNC machines to perform machine sealing and apply two-component polyurethane seals of various thicknesses to various forms of 2D geometry of products.

With appropriate preparation, sealing is possible on various types of material:

- painted surfaces

- stainless sheet metal

- plastic

- glass

- aluminum, etc.

| Design dimensions | |

|---|---|

| Max product dimensions (h x w x d) | 2200 × 1200 × 400 mm |

| IP ratings | IP 68 |

| Polyurethane two-component seal | |

|---|---|

| Component A | FERMAPOR K31-A-9230-2-VP |

| Component B | FERMAPOR-K31-B-3 |

| Seal color | black |

| Temperature stability | od –40 °C +100 °C (kratek čas do +160 °C) |

| Water absorption | < 3,5 % |

| Fire resistance | UL50 |

| Hardness | 55-65 Shore |

Stamping of fasteners

On the HAEGER 824 One Touch 4e LITE, we stamp the fasteners into the sheet metal.

We produce press-in bushings, press-in nuts, press-in screws from steel, stainless steel or aluminum, from sizes M3 to M8.

The stamping force of the machine is 72 kN.

The stamping speed is up to 1400 stamps per hour.

The machine enables automatic feeding of the stamping material and tool change.

Edge rounding

In the factory, we also offer reshaping/rounding of the edges on various lids, trays, panels, doors and other simple products with reinforced edges. The work is carried out by the ACF Cornerformer.

By rounding the edges of the product after bending, there is no need to weld and grind.

Edges can be rounded to different radiuses – R4 and R6.

The height of the edge on the product can be up to 30 mm, depending on the thickness and type of material.

Surface treatment

Surface treatment provides the best surface protection for products. We perform several different techniques for high-quality finishes on sheet metal.

Powder and wet coating of sheet metal

You choose the color according to the RAL scale. The standard coating thickness is from 60 to 120 microns, but we can adjust it to your needs. Painted surfaces can be full gloss, matte or semi-gloss, with a coarse, fine or smooth texture or as desired.

Cataphhoretic coating

The electrophoretic dyeing process ensures perfect coating results and anti-corrosion protection even with the shaped pieces. In combination with powder coating, we achieve a very high level of anti-corrosion protection.

Galvanic and hot-dip galvanizing

Higher quality and more durable anti-corrosion protection compared to painting and the most environmentally friendly.

Picking, passivation and electropolishing

A chemical process that removes iron oxides from surfaces to provide better stainless steel properties. Electropolishing produces a product with an extremely smooth and glossy surface.

Quality and trust

We are proud of our obtained certificates, which prove the professionalism and competences of our staff and the achievement of the required quality standards.

With a process approach, monitoring, management, measurements and implementation of preventive measures, we prove to our customers, suppliers, cooperators and employees that we are aware of the importance of the quality of our products and services and are committed to continuous improvements.

Our promise

With larger production facilities and a larger and more powerful machine park, we are more flexible, and at the same time we offer you more capacity to realize your needs and wishes.

Technology partner

A smart factory with state-of-the-art technology – Industry 4.0

Strategic partner

Comprehensive service from development to the product.

Sustainable partner

Responsibility to

environment, employees

and company.